+86 18030169616

+86 18030169616

allen@crtopmachine.com

allen@crtopmachine.com

+86 18030169616

+86 18030169616

allen@crtopmachine.com

allen@crtopmachine.com

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

read more

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

read more

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

read more

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

read more

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

read more

With the rapid development of biotechnology and pharmaceutical industry, bioreactors, as core production equipment, are increasingly used in cell culture, enzymatic reaction, fermentation engineering ...

SEND A MESSAGE :

WhatsA pp : +8618030169616 Tel .: +86 18030169616

Email : allen@crtopmachine.com Skype : +8618030169616

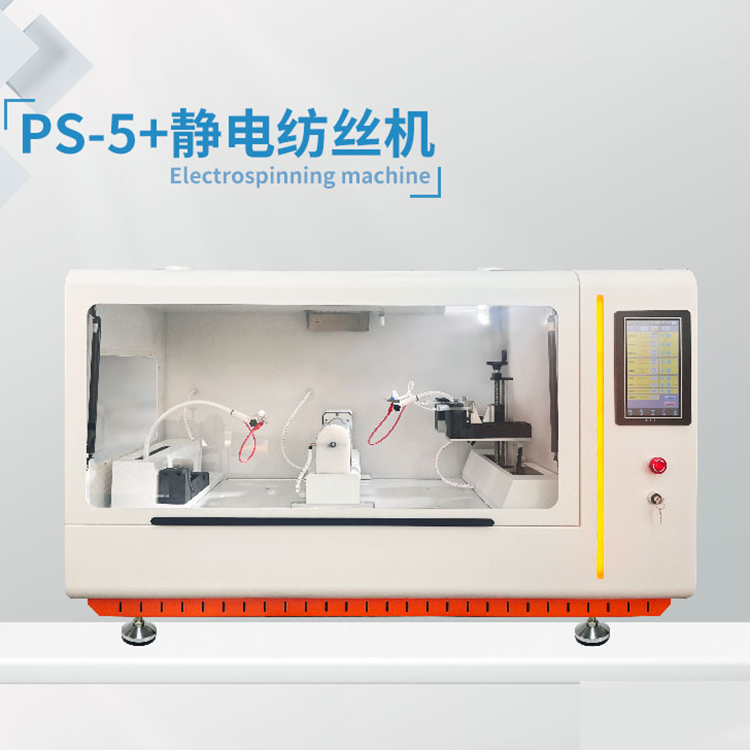

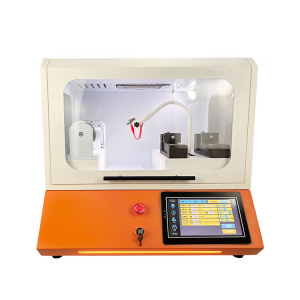

Item No.:

PS-5+Product Origin:

ChinaShipping Port:

Xiamen (Or any port in China)Min Order:

1Lead Time:

7-10 daysMinimum Order Quantity:

1Operation method:

Semi automatic touch buttonScreen:

PLC controlVoltage:

220/110Warranty:

1 yearDelivery Time:

6-8DayPackaging Details:

Standard export wooden boxPS-5+ Electrostatic Spinning Machine is used for electrostatic spinning technology to prepare nanofibres and other needs, with intelligent environment control, safety protection, exhaust lighting, 360-degree spinning observation light and other functions, to provide a safe and stable experimental environment for electrostatic spinning.

Product specifications

Double High Voltage Power Supply

1: Output voltage

Voltage DC: 0~+30KV (Optional 0-50KV) Current: < 1mA Input voltage: AC220V + 10%

2:Output voltage

Voltage DC: 0~-30KV Current:< 1mA Input voltage: AC220V + 10%

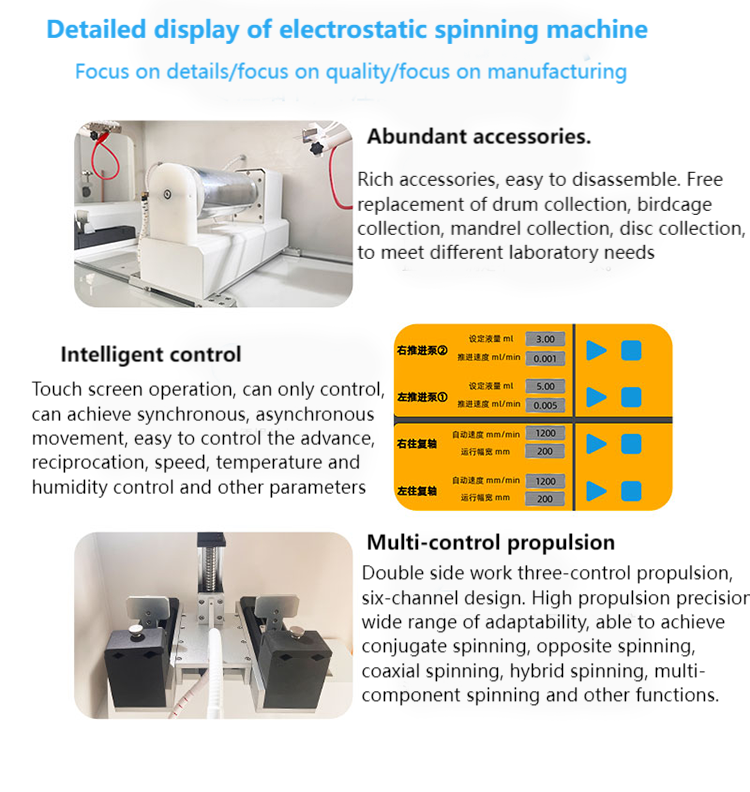

Fluid supply system

1:Three groups of propulsion control, all can be controlled independently. Positive pole with two sets of propulsion control, each set of propulsion two channels, a total of four channels. Negative with a group of propulsion control, two channels. Meet the function of coaxial spinning, conjugate spinning, multi-needle spinning, hybrid spinning, etc.

2:Injection rate, injection volume, injection time can be freely controlled, automatic liquid supply speed range:0.001-20 ml/h.

3:Can be used in high-voltage environment, reliable insulation system, not easy to breakdown

4:Wide range of application, can be applied to syringes: 1ml, 2ml, 5ml, 10ml, 20ml, 50ml and so on.

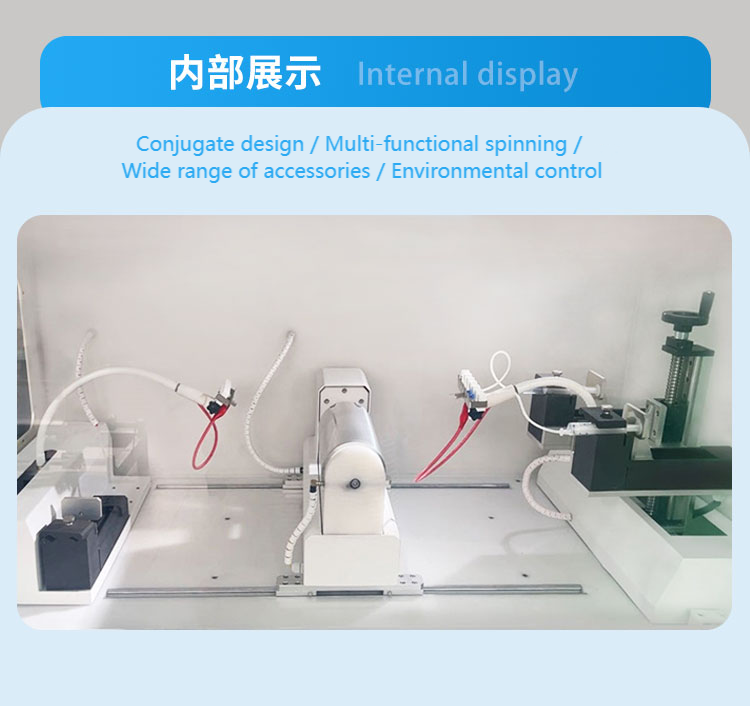

Collecting device

1:High-speed collection drum: speed 200-4500r/min continuously adjustable

Drum diameter:100mm Length:200mm

2:Collected samples are unfolded to the size of A4 paper. Normal fibre collection and improved fibre homogeneity can be achieved. Higher speeds enable orderly collection of nanofibres.

3:Collection plate material: corrosion-resistant stainless steel Plate size: 200*200mm.

Birdcage collection, mandrel collection, disc collection are optional.

Nozzle three-axis movement

1:X-axis: manual displacement slide table

2:Y-axis: automatic reciprocating motion platform, two groups, left and right symmetrical arrangement, can achieve synchronous motion, asynchronous motion

3:Reciprocating stroke: 0-200mm, reciprocating distance, reciprocating times, reciprocating speed can be set.

4:Z-axis: manual lifting table

5:Configuration bracket: support for 6-needle spinning, parallel spinning, multi-needle spinning, coaxial spinning, conjugate spinning and so on.

Environmental Control System

1:Humidity control

External dehumidifier, direct supply of dry hot air, fast and effective reduction of environmental humidity within the equipment to improve the spinning effect.

2:Temperature control

Infrared heating to increase the temperature and accelerate the evaporation of solvents for fibre forming

3:Exhaust system

Built-in exhaust fan, can quickly replace the organic gas in the chamber, effectively avoid the discharge of the spinning head to ignite the organic gas.

4:Lighting System

With operating lamp, can observe the spinning process.

Intelligent control system

1:10-inch man-machine interface, self-developed numerical control system control (high-voltage power supply, nozzle moving device, liquid supply system control, heating control, temperature control, exhaust gas control, experimental timing control and lighting and other parts of the operation) and monitoring the status of each section

2:Spinning time can be set, timed to automatically shut down the equipment to ensure safety

3:With automatic parameter recording and saving function

Safety Protection

1: Safety Protection

1:Equipped with discharge short-circuit protection, equipped with leakage protection

2:Grounding and static elimination system, to avoid electric charge accumulation caused by electric shock, fire, explosion and other accidents.

3:With inert gas access function.

Spinning Chamber

1:Built-in 360-degree spotlight, convenient to observe the spinning experiment.

2:Three sides of the window, multi-angle observation of the spinning state

3:Lift up the door to increase the operating space.

Product Details

SEND A MESSAGE:

WhatsApp: +8618030169616 Tel.: +86 18030169616(Only supports mobile phone dialing)

Email: Jackson@crtopmachine.com Skype: +8618030169616

Add.: Haicang District, Xiamen , Fujian , China.

Professional Laboratory Nanofiber Electrostatic Spinning Machine

Professional Laboratory Nanofiber Electrostatic Spinning Machine

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

PCL Material Nano-fiber Coaxial Nozzle Electrospinning

PCL Material Nano-fiber Coaxial Nozzle Electrospinning

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Laboratory Nano Electrospinning System with High Voltage Soucer and Collection Device

Laboratory Nano Electrospinning System with High Voltage Soucer and Collection Device

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Intelligent control Nano Electrospinning System with Collection Device

Intelligent control Nano Electrospinning System with Collection Device

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Air Spinning Machine

Air Spinning Machine

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Assembled Electrostatic Spinning Machine

Assembled Electrostatic Spinning Machine

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Multi-functional Laboratory Electrostatic Spinning Machine

Multi-functional Laboratory Electrostatic Spinning Machine

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Standard Test Electrostatic Spinning Machine

Standard Test Electrostatic Spinning Machine

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Roll material unwinder with web guide

Roll material unwinder with web guide

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Copyright © One-stop Service for Printing Machinery-Xiamen CRTOP Machinery Co., Ltd