+86 18030169616

+86 18030169616

allen@crtopmachine.com

allen@crtopmachine.com

+86 18030169616

+86 18030169616

allen@crtopmachine.com

allen@crtopmachine.com

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

read more

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

read more

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

read more

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

read more

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

read more

With the rapid development of biotechnology and pharmaceutical industry, bioreactors, as core production equipment, are increasingly used in cell culture, enzymatic reaction, fermentation engineering ...

Min Order:

1Minimum Order Quantity:

1Operation method:

PLCScreen:

Touch ScreenCapacity:

100LWarranty:

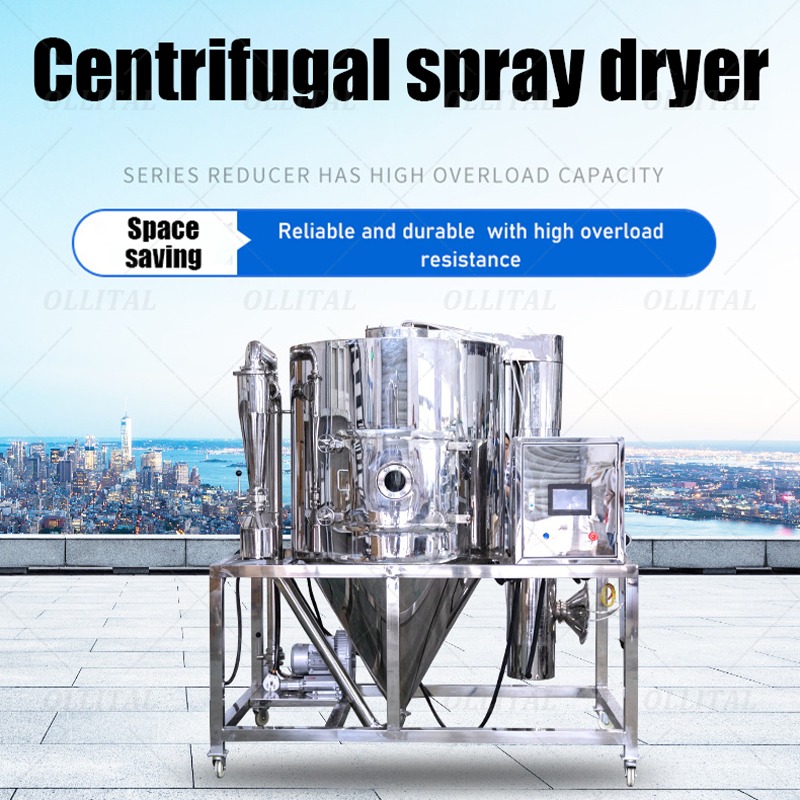

1 yearSpray drying technology has been widely used in liquid forming and drying processes due to its excellent efficiency and flexibility.

It is particularly suitable for the process of preparing powder or granular products from solution or paste raw materials. During the production process, the particle size, distribution density and residual moisture content of the product are precisely controlled to ensure that the final product meets high quality standards.

Whether it is pharmaceutical preparations, food additives and other industries, spray drying can provide an ideal and efficient solution.

The material passes through the filter, heater, drying cylinder, and hot air flows into the drying cylinder evenly in a spiral shape. The liquid material is pumped from the material box through the filter into the centrifugal atomizer of the dryer, and the liquid material is sprayed into very fine mist droplets, which flow parallel to the hot air, and the water evaporates quickly, and the powdered finished product can be obtained quickly. The product is discharged through the lower part of the drying tower and the cyclone, and the exhaust gas is discharged through the blower.

Industrial Materials :catalyst, glass material, fireproof material, cellulose, pulp carbon material, superconducting material fine ceramic, carbon powder, piezoelectric ceramic, semiconductor material, magnetic material, optical fiber material, etc.

Chemicals :Polymers, pigments, yeast enzymes, surfactants, cosmetics, disperse dyes, reactive dyes, organic catalysts, etc.

Steel and Metals:Rare metals, alloys, rare earth materials, etc.

Food Industry:Density milk powder, lecithin, cocoa powder, milk substitute, Corn starch, glucose, instant tea egg white , etc.

5. The product has good dispersibility, fluidity and solubility, and the particle size, looseness and water content of the product can be adjusted within a certain range.

Other types of spray dryers

5L 10L 15L Milk Egg Instant Coffee Ceramic Powder Centrifugal Precio Para Spray Dryer Machine

5L 10L 15L Milk Egg Instant Coffee Ceramic Powder Centrifugal Precio Para Spray Dryer Machine

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Lab 2L 5L 10L Lab Small Mini Food Egg Coconut Milk Pharmaceutical Ceramic Chemical Ceramic Nano Centrifugal Spray Dryer

Lab 2L 5L 10L Lab Small Mini Food Egg Coconut Milk Pharmaceutical Ceramic Chemical Ceramic Nano Centrifugal Spray Dryer

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

1.5-2 L/h Mini Lab Coffee Milk Powder Spray dryer

1.5-2 L/h Mini Lab Coffee Milk Powder Spray dryer

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Lab Coffee Tea Plant Milk Powder Spray Dryer

Lab Coffee Tea Plant Milk Powder Spray Dryer

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Industrial Centrifugal Nozzle Spray Dryer Machine

Industrial Centrifugal Nozzle Spray Dryer Machine

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

3000ml/h Lab Milk Spray Dryer Powder Machine

3000ml/h Lab Milk Spray Dryer Powder Machine

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Lab PLC Control System Mini Stainless Steel Spray Dryer

Lab PLC Control System Mini Stainless Steel Spray Dryer

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel: +86 18030169616 Email: allen@crtopmachine.com jackson@crtopmachine.com

Coffee Tea Flavored Meat Fat-rich Milk Powder Spray Dryer

Coffee Tea Flavored Meat Fat-rich Milk Powder Spray Dryer

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Atomization Vacuum Milk Centrifugal Spray Dryer

Atomization Vacuum Milk Centrifugal Spray Dryer

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Copyright © One-stop Service for Printing Machinery-Xiamen CRTOP Machinery Co., Ltd