+86 18030169616

+86 18030169616

allen@crtopmachine.com

allen@crtopmachine.com

+86 18030169616

+86 18030169616

allen@crtopmachine.com

allen@crtopmachine.com

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

read more

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

read more

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

read more

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

read more

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

read more

With the rapid development of biotechnology and pharmaceutical industry, bioreactors, as core production equipment, are increasingly used in cell culture, enzymatic reaction, fermentation engineering ...

Min Order:

1Minimum Order Quantity:

1Operation method:

PLCScreen:

Touch ScreenCapacity:

100LWarranty:

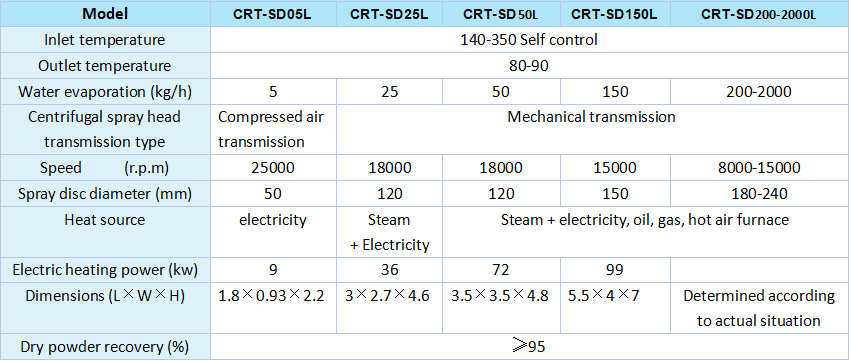

1 yearCentrifugal spray dryer is a kind of equipment commonly used in pharmaceutical, food, chemical and other industries. It can quickly dry liquid materials into powder or granular solids. This equipment uses spray drying technology to spray liquid materials into fine droplets and quickly evaporate the water in them to obtain dry solid products.

Collecting the product: The dried solid particles are carried by the air flow to a separator (such as a cyclone separator), where the solid material is collected and the dried air is discharged from the system.

Fast drying speed: Due to the small droplet size, the drying process is extremely fast, generally only a few seconds.

Good product quality: The dried product has uniform particle size distribution, good fluidity and solubility.

Strong adaptability: Suitable for processing heat-sensitive materials, the drying process will not cause overheating or degradation of the product.

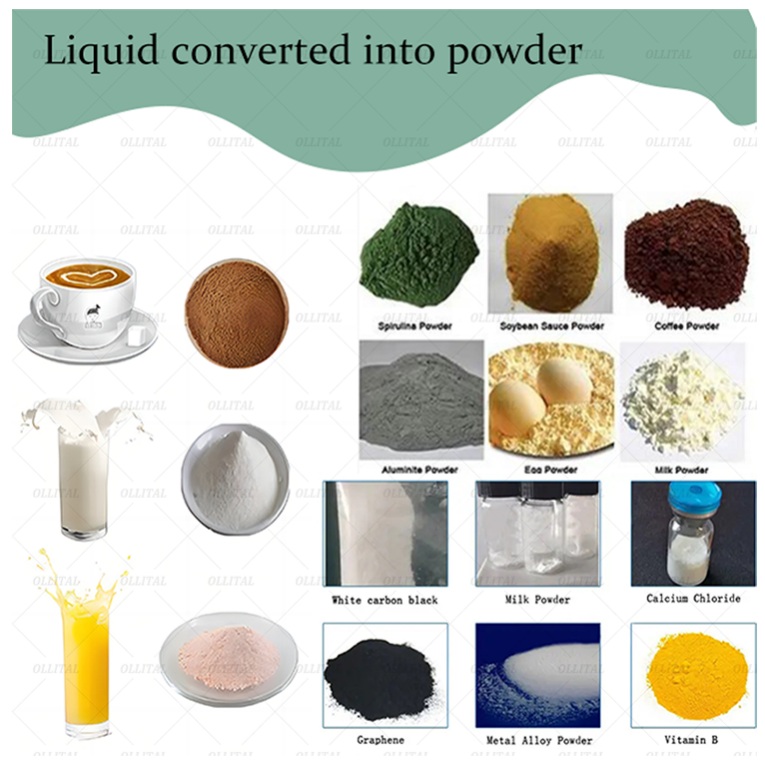

Food industry: production of milk powder, coffee, egg powder, spices, etc.

Chemical industry: production of dyes, catalysts, resins, ceramic powders, etc.

Plastic resin:AB, ABS latex, urea-formaldehyde resin, phenolic resin,

5L 10L 15L Milk Egg Instant Coffee Ceramic Powder Centrifugal Precio Para Spray Dryer Machine

5L 10L 15L Milk Egg Instant Coffee Ceramic Powder Centrifugal Precio Para Spray Dryer Machine

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Lab 2L 5L 10L Lab Small Mini Food Egg Coconut Milk Pharmaceutical Ceramic Chemical Ceramic Nano Centrifugal Spray Dryer

Lab 2L 5L 10L Lab Small Mini Food Egg Coconut Milk Pharmaceutical Ceramic Chemical Ceramic Nano Centrifugal Spray Dryer

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

1.5-2 L/h Mini Lab Coffee Milk Powder Spray dryer

1.5-2 L/h Mini Lab Coffee Milk Powder Spray dryer

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Lab Coffee Tea Plant Milk Powder Spray Dryer

Lab Coffee Tea Plant Milk Powder Spray Dryer

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Industrial Centrifugal Nozzle Spray Dryer Machine

Industrial Centrifugal Nozzle Spray Dryer Machine

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

3000ml/h Lab Milk Spray Dryer Powder Machine

3000ml/h Lab Milk Spray Dryer Powder Machine

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Lab PLC Control System Mini Stainless Steel Spray Dryer

Lab PLC Control System Mini Stainless Steel Spray Dryer

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel: +86 18030169616 Email: allen@crtopmachine.com jackson@crtopmachine.com

Coffee Tea Flavored Meat Fat-rich Milk Powder Spray Dryer

Coffee Tea Flavored Meat Fat-rich Milk Powder Spray Dryer

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Atomization Vacuum Milk Centrifugal Spray Dryer

Atomization Vacuum Milk Centrifugal Spray Dryer

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Copyright © One-stop Service for Printing Machinery-Xiamen CRTOP Machinery Co., Ltd