+86 18030169616

+86 18030169616

allen@crtopmachine.com

allen@crtopmachine.com

+86 18030169616

+86 18030169616

allen@crtopmachine.com

allen@crtopmachine.com

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

read more

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

read more

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

read more

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

read more

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

read more

With the rapid development of biotechnology and pharmaceutical industry, bioreactors, as core production equipment, are increasingly used in cell culture, enzymatic reaction, fermentation engineering ...

SEND A MESSAGE :

WhatsA pp : +8618030169616 Tel .: +86 18030169616

Email : allen@crtopmachine.com Skype : +8618030169616

Item No.:

OLT-SD10LMin Order:

1Compliance:

CE CertifiedMinimum Order Quantity:

1Operation method:

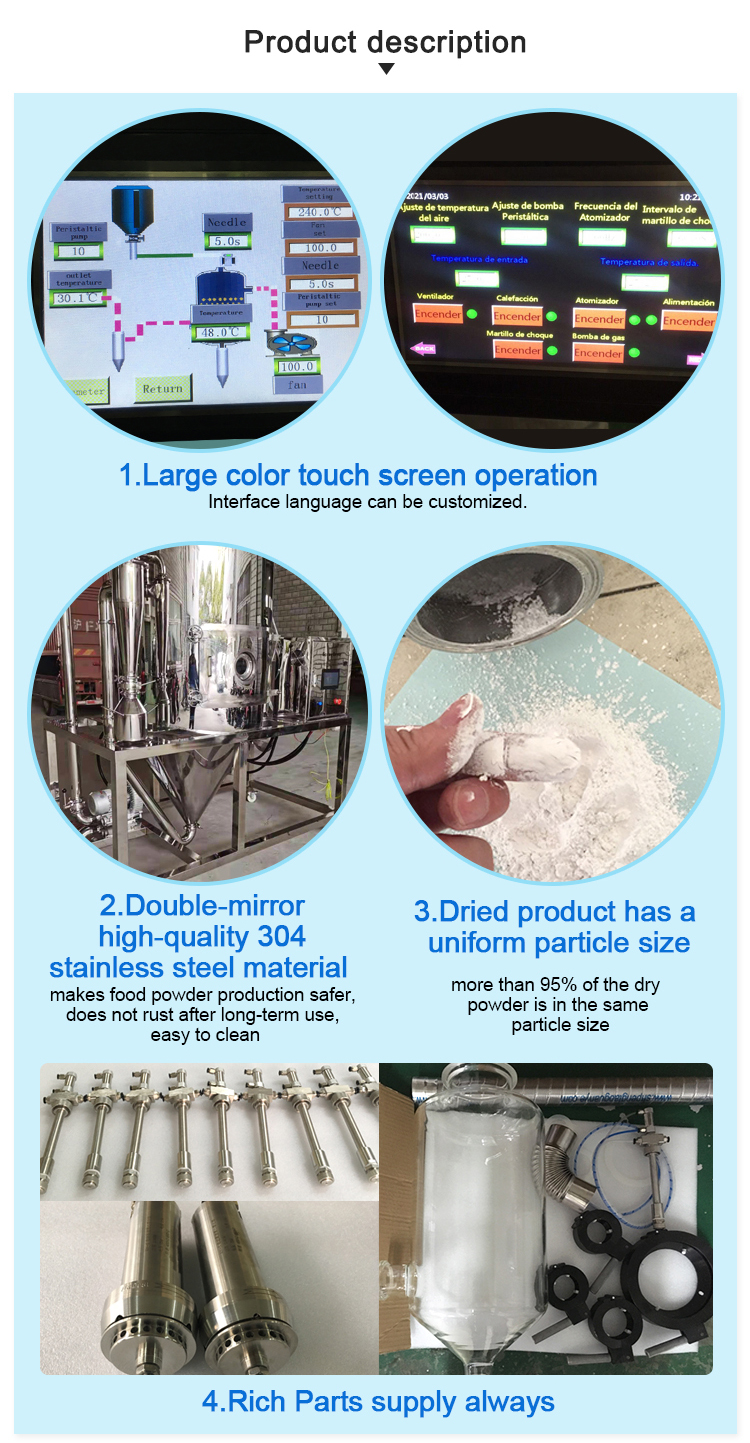

PLC controlScreen:

Touch ScreenCapacity:

10L/hVoltage:

380V/50HzWarranty:

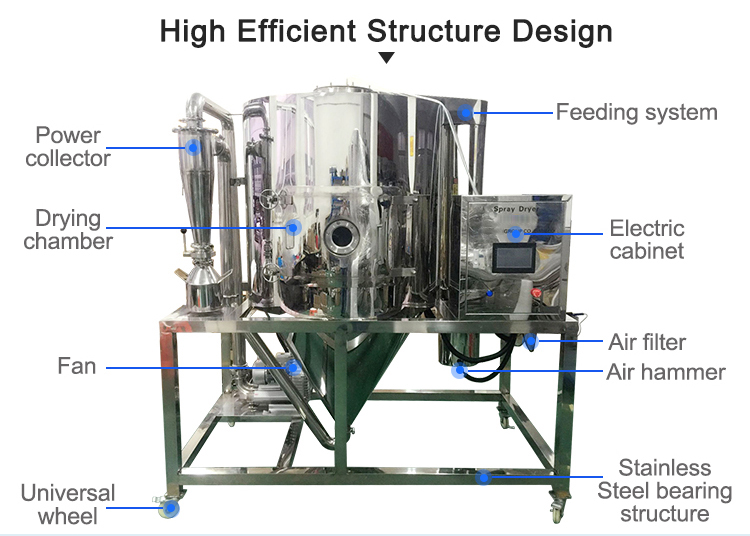

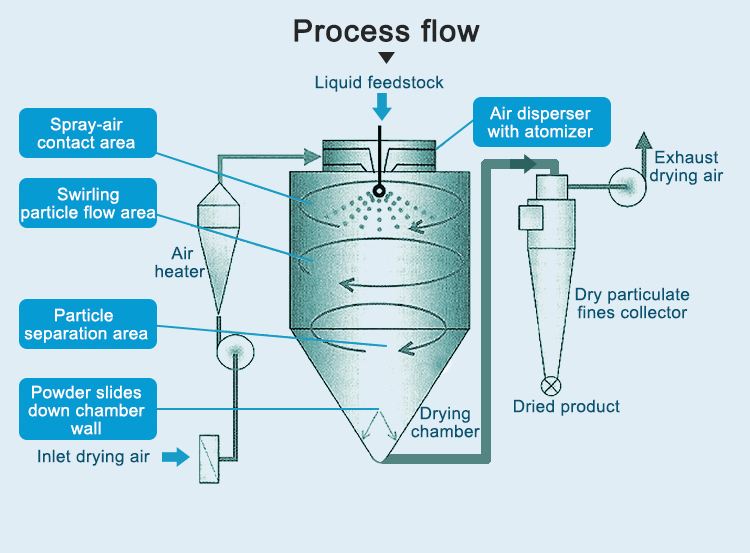

1 yearspray dryer is a kind of continuous atmospheric dryer.Use pneumatic or electric atomization device to make liquid high-speed centrifugal spray as fog droplet, make these fog droplet contact with the hot air in the drying chamber and instantaneous drying.

Parameters

|

Name |

OLT-SD10L |

|

Inlet air temperature control |

≤30-300 °C. |

|

Outlet air temperature control |

<30 ~ 150 °C. |

|

Maximum evaporation of water |

200-10L/h. |

|

Centrifugal spray head transmission form |

Electric. |

|

Speed |

40,000 rpm |

|

Spray disc diameter |

80mm |

|

Heat source |

Electricity |

|

Electric heating maximum power |

18kw |

|

Total power |

22kw |

|

Dimensions L*W*H(mm) |

2500*1600*2800 |

|

Dry powder recovery |

≥98% |

Configuration List

| S.N. | Name | Specification | Material | Quantity |

| 1 | OLT-SD10L spray dryer | 2500*1600*2800 | Stainless steel | 1 |

| 2 | Tower body | Φ1400*2600 | Stainless steel | 1 |

| 3 | Centrifugal nozzle atomizer | Φ80 10kg per hour | Stainless steel | 1 |

| 4 | Air compressor / vibrating air hammer | Matching | Stainless steel | 2 |

| 5 | Cyclone separator | Φ300 | Stainless steel | 1 |

| 6 | Peristaltic pump | 30-100L/h-0.55kw | Stainless steel | 1 |

| 7 | Induced draft fan | 4kw | Q235A steel | 1 |

| 8 | Electric heaters | 18kw | Stainless steel | 1 |

| 9 | air filter | Matching | Sainless steel | 1 |

| 10 | Electrical control box | PLC | Stainless steel | 1 |

| 11 | Inlet and out wind temperature detector | Matching | Stainless steel | 2 |

| 12 | Air duct | Matching | Stainless steel | 1 |

| 13 | Receiving cylinder | 10L | stainless steel | 1 |

| 14 | Cylinder insulation | 50mm | Insulation cotton | |

| 15 | support | 60*60mm | Stainless steel | 1 |

Air through filtering and heating, enter the hot air distributor which is at the top of spray dryer, hot air spiraling evenly into the drying chamber. Liquid through the high-speed centrifugal automizer which is at the top of drying chamber, (rotating) centrifugal spray into tiny fog droplet, then contact with the hot air flow, drying finish product in a very short time and whereabouts. Finished product output continuously between the drying tower bottom and cyclone separator, exhaust through dust catcher emptying by induced draft fan.

WhatsApp: +8618030169616 Tel.: +86 18030169616(Only supports mobile phone dialing)

Email: Jackson@crtopmachine.com Skype: +8618030169616

Add.: Haicang District, Xiamen , Fujian , China.

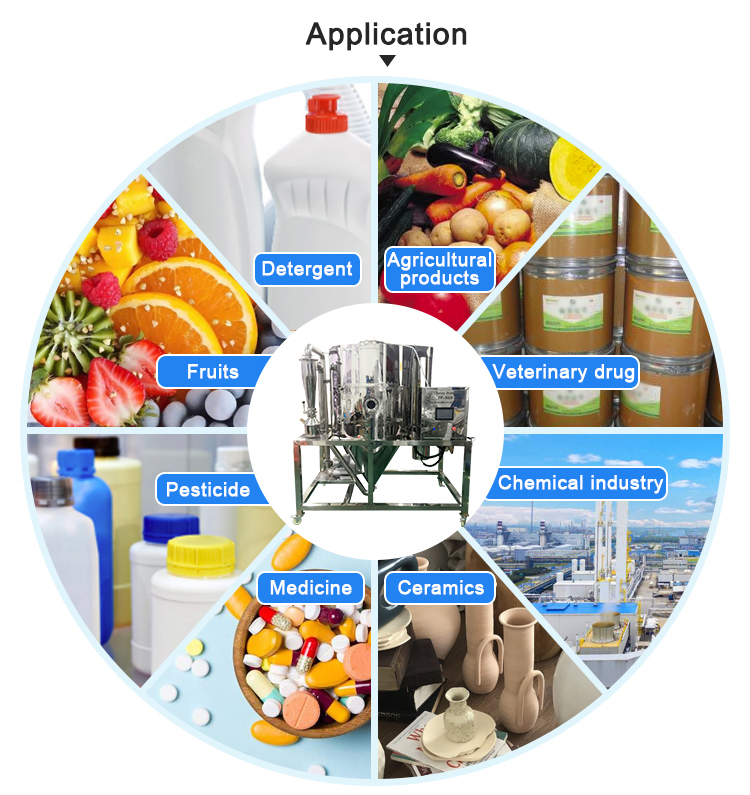

5L 10L 15L Milk Egg Instant Coffee Ceramic Powder Centrifugal Precio Para Spray Dryer Machine

5L 10L 15L Milk Egg Instant Coffee Ceramic Powder Centrifugal Precio Para Spray Dryer Machine

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Lab 2L 5L 10L Lab Small Mini Food Egg Coconut Milk Pharmaceutical Ceramic Chemical Ceramic Nano Centrifugal Spray Dryer

Lab 2L 5L 10L Lab Small Mini Food Egg Coconut Milk Pharmaceutical Ceramic Chemical Ceramic Nano Centrifugal Spray Dryer

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

1.5-2 L/h Mini Lab Coffee Milk Powder Spray dryer

1.5-2 L/h Mini Lab Coffee Milk Powder Spray dryer

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Lab Coffee Tea Plant Milk Powder Spray Dryer

Lab Coffee Tea Plant Milk Powder Spray Dryer

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

3000ml/h Lab Milk Spray Dryer Powder Machine

3000ml/h Lab Milk Spray Dryer Powder Machine

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Lab PLC Control System Mini Stainless Steel Spray Dryer

Lab PLC Control System Mini Stainless Steel Spray Dryer

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel: +86 18030169616 Email: allen@crtopmachine.com jackson@crtopmachine.com

Coffee Tea Flavored Meat Fat-rich Milk Powder Spray Dryer

Coffee Tea Flavored Meat Fat-rich Milk Powder Spray Dryer

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Atomization Vacuum Milk Centrifugal Spray Dryer

Atomization Vacuum Milk Centrifugal Spray Dryer

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

3L Stainless Steel Spray Dryer

3L Stainless Steel Spray Dryer

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Copyright © One-stop Service for Printing Machinery-Xiamen CRTOP Machinery Co., Ltd