+86 18030169616

+86 18030169616

allen@crtopmachine.com

allen@crtopmachine.com

+86 18030169616

+86 18030169616

allen@crtopmachine.com

allen@crtopmachine.com

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

read more

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

read more

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

read more

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

read more

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

read more

With the rapid development of biotechnology and pharmaceutical industry, bioreactors, as core production equipment, are increasingly used in cell culture, enzymatic reaction, fermentation engineering ...

SEND A MESSAGE :

WhatsA pp : +8618030169616 Tel .: +86 18030169616

Email : allen@crtopmachine.com Skype : +8618030169616

Item No.:

OLT-SD8000STMin Order:

1Minimum Order Quantity:

1Operation method:

PLCScreen:

Touch ScreenCapacity:

2LVoltage:

220V/50HzWarranty:

1 year

Spray drying machine is especially suitable for drying the heat sensitive materials, after drying, there's no need for smashing and sorting, so as to reduce the operation procedures and save your time.

Parameter

| Model | OLT-SD8000ST |

| Max capacity | 1500-2000ml/h |

| Temperature range of Inlet air | 30℃ - 300℃ |

| Temperature range of outlet air | 30℃ -150℃ |

| Precision of temperature | ± 1 ℃ |

| Dryer time | 1.0-1.5 S |

| Speed of squirmy pump | 550-2000ml/h, |

| Consume of dryer air | 0-330m3 /h, max pressure: 686Pa |

| Consume of spray air | 0-4.2m3 /h, spray pressure: 2-5bar |

| Spray system | 2 liquid nozzles with standard 1.0mm nozzle |

| Options of 0.5/0.7/1.5/2.0/2.5mm | |

| Spray direction | Downwards co-current |

| Power | 3.5KW 108V-240V |

| Dimensions |

650*500*1550 ( mm ) L * W* H |

| Small spray dryer configuration | |

| 1. Atomizer | 9.Peristaltic pump |

| 2. Large clamp | 10. Drying room |

| 3. Exhaust pipe | 11. Touch screen |

| 4, lock nut | 12, 2# clamps |

| 5. Cyclone separator | 13. Power switch |

| 6, 1# clamp | 14.Feeding tube |

| 7. Collection bottles | 15.3# clamps |

| 8. Large clamp | 16.Collection tube |

Accessories

| Name | Quantity |

| Glass drying room | 1 |

| Glass cyclone separator | 2 |

| Glass sample collection bottle | 2 |

| Glass sample waste bottle | 1 |

| Conveying silicone tube 6mm | 2 meters |

| Spray cavity | 1 |

| Clamp (LY12 black) | 6 |

Feature

1. High-tech nozzle,high efficiency.

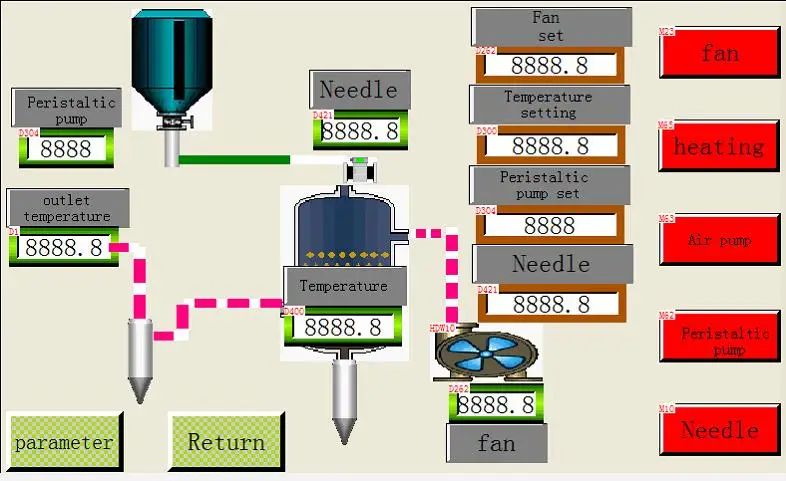

2. LCD touch-screen display:inlet air temperature/outlet air temperature/pump speed/air volume/needle frequency.

3. Nozzle cleaner(needle)is set in the machine,and nozzle can be cleaned automaticaly by the needle when blocked.Needle frequency can be adjusted.

4. Shutdown protection function:the system will stop when pressing the stop botton,all parts except the fan will stop working.Heating system won’t be damaged in this way.

5. Material won’t get polluted due to the special material of the atomizing.

drying and collection system.

6. Two-fluid nozzle,stainless steel,compact stucture,no accessory device.

7. PID constant temperature control,precise temperature control,precision is ±1℃.

8. Feed rate can be adjusted by the peristaltic pump,Min. samples can reach 30ml.

9. Uniform product powder,above 95% powder keep within same size range.

Detail Images

Application

1. Chemical industry: hydrated silica, concrete additives, barium sulfate, basic chromic sulfate, alumina, titania, kaolin, ferrite, steatite, carbide, fertilizers, dyes, scouring agents, ACR assistants, latex, water purifiers, resins, plastics, cryolite.

2. Food Industry: dextrin, maltose, albumen powder, vitelline powder, compound sugar, granular grease, instant coffee, amylum, flavors, garden stuff. It is applied in drying of some kinds of liquid material, such as solutions, emulsions, suspensions, liquid pastes, etc.

3. Dairy: skim milk powder, whole milk powder, soy milk powder, ice cream powder, milk extract powder, etc.

4. Pharmaceutical industry: Chinese drugs and western medicine powder, antibiotics, biochemical products, vitamins, pesticides, hydrolyzed proteins, enzymes, single cell proteins, etc.

5. Building material industry: ceramic body, frit, superfine powder.

6. Environmental protection: flue gas desulfurization, disposal of black liquor and wastewater of pharmaceutical factories.

7. Others: fishmeal waste, feed, etc.

WhatsApp: +8618030169616 Tel.: +86 18030169616(Only supports mobile phone dialing)

Email: Jackson@crtopmachine.com Skype: +8618030169616

Add.: Haicang District, Xiamen , Fujian , China.

5L 10L 15L Milk Egg Instant Coffee Ceramic Powder Centrifugal Precio Para Spray Dryer Machine

5L 10L 15L Milk Egg Instant Coffee Ceramic Powder Centrifugal Precio Para Spray Dryer Machine

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Lab 2L 5L 10L Lab Small Mini Food Egg Coconut Milk Pharmaceutical Ceramic Chemical Ceramic Nano Centrifugal Spray Dryer

Lab 2L 5L 10L Lab Small Mini Food Egg Coconut Milk Pharmaceutical Ceramic Chemical Ceramic Nano Centrifugal Spray Dryer

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

1.5-2 L/h Mini Lab Coffee Milk Powder Spray dryer

1.5-2 L/h Mini Lab Coffee Milk Powder Spray dryer

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Lab Coffee Tea Plant Milk Powder Spray Dryer

Lab Coffee Tea Plant Milk Powder Spray Dryer

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Industrial Centrifugal Nozzle Spray Dryer Machine

Industrial Centrifugal Nozzle Spray Dryer Machine

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

3000ml/h Lab Milk Spray Dryer Powder Machine

3000ml/h Lab Milk Spray Dryer Powder Machine

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Lab PLC Control System Mini Stainless Steel Spray Dryer

Lab PLC Control System Mini Stainless Steel Spray Dryer

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel: +86 18030169616 Email: allen@crtopmachine.com jackson@crtopmachine.com

Atomization Vacuum Milk Centrifugal Spray Dryer

Atomization Vacuum Milk Centrifugal Spray Dryer

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

3L Stainless Steel Spray Dryer

3L Stainless Steel Spray Dryer

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Copyright © One-stop Service for Printing Machinery-Xiamen CRTOP Machinery Co., Ltd