+86 18030169616

+86 18030169616

allen@crtopmachine.com

allen@crtopmachine.com

+86 18030169616

+86 18030169616

allen@crtopmachine.com

allen@crtopmachine.com

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

read more

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

read more

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

read more

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

read more

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

read more

With the rapid development of biotechnology and pharmaceutical industry, bioreactors, as core production equipment, are increasingly used in cell culture, enzymatic reaction, fermentation engineering ...

SEND A MESSAGE :

WhatsA pp : +8618030169616 Tel .: +86 18030169616

Email : allen@crtopmachine.com Skype : +8618030169616

Item No.:

CRT-XPM-17Product Origin:

FujianShipping Port:

Xiamen/ShanghaiMin Order:

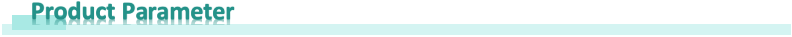

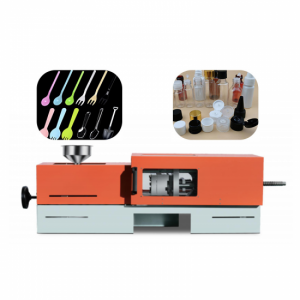

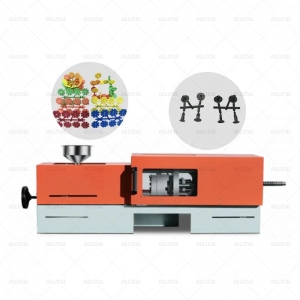

1Injection molding machine is a machine that heats and melts plastic materials, injects the molten plastic into a mold cavity under high pressure, and forms a product after cooling. It is widely used in the production of various plastic products, such as daily necessities, electronic product housings, and auto parts. The injection molding process involves heating, injection, pressure holding, cooling, and demoulding. The entire process is highly automated and efficient.

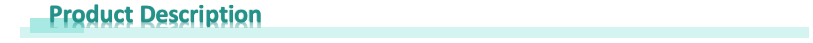

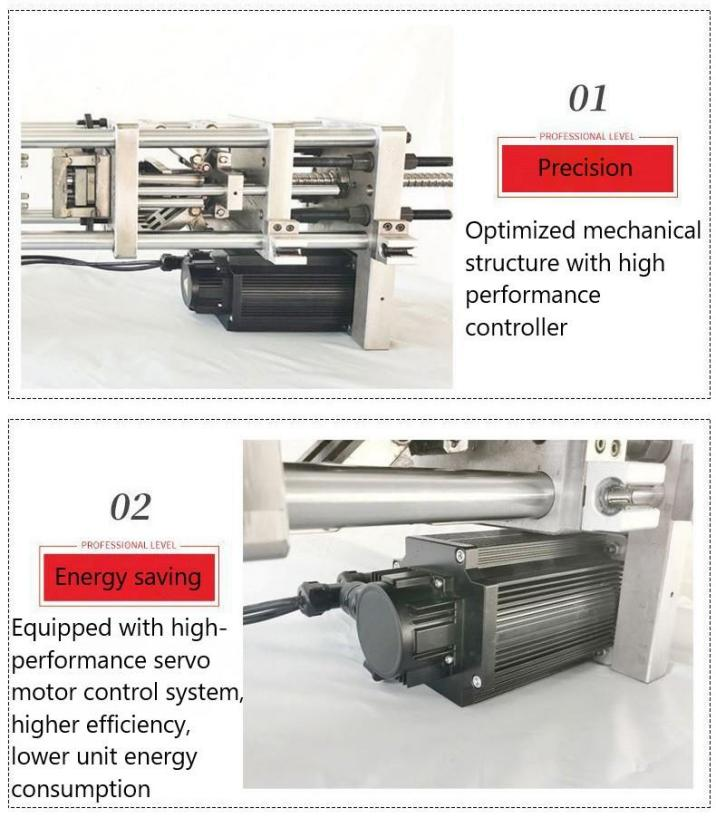

The working principle of the injection molding machine is similar to that of a syringe used for injections. It uses the thrust of the screw (or plunger) to inject the plasticized molten state (i.e., viscous flow state) plastic into the closed mold cavity, and obtains the product after solidification and shaping.Injection molding is a cyclic process, and each cycle mainly includes: quantitative feeding - melt plasticization - pressure injection - mold filling and cooling - mold opening and part removal. After the plastic part is taken out, the mold is closed again for the next cycle.

CRTOP Brand Small Horizontal Type Plastic Injection Moulding Machine

CRTOP Brand Small Horizontal Type Plastic Injection Moulding Machine

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

CRTOP Brand Lab Small Horizontal Type Plastic Injection Molding Machine

CRTOP Brand Lab Small Horizontal Type Plastic Injection Molding Machine

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Desktop Small PP PE PA6 PS PEI PMMA PVC ABS TPU PET Plastic Electric Mould Injection Molding Machine

Desktop Small PP PE PA6 PS PEI PMMA PVC ABS TPU PET Plastic Electric Mould Injection Molding Machine

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Horizontal PVC ABS PC PlasticBottle-Cap Making Injection Molding Machine

Horizontal PVC ABS PC PlasticBottle-Cap Making Injection Molding Machine

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Lab Injection Molding Machine Table Injection Molding Machine

Lab Injection Molding Machine Table Injection Molding Machine

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Plastic Injection Molding Machine With Servo Motor Tableware Injection Molding Machine

Plastic Injection Molding Machine With Servo Motor Tableware Injection Molding Machine

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Full Automatic Plastic Injection Molding Machine Table Top Plastic Injection Molding Machine

Full Automatic Plastic Injection Molding Machine Table Top Plastic Injection Molding Machine

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel : +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Horizontal Injection Molding Machine

Horizontal Injection Molding Machine

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel : +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Preform Injection Molding Machine Pet injection molding machine

Preform Injection Molding Machine Pet injection molding machine

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel : +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Copyright © One-stop Service for Printing Machinery-Xiamen CRTOP Machinery Co., Ltd