+86 18030169616

+86 18030169616

allen@crtopmachine.com

allen@crtopmachine.com

+86 18030169616

+86 18030169616

allen@crtopmachine.com

allen@crtopmachine.com

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

read more

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

read more

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

read more

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

read more

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

read more

With the rapid development of biotechnology and pharmaceutical industry, bioreactors, as core production equipment, are increasingly used in cell culture, enzymatic reaction, fermentation engineering ...

SEND A MESSAGE :

WhatsA pp : +8618030169616 Tel : +86 18030169616

Email : allen@crtopmachine.com Skype : +8618030169616

Item No.:

CRT-XPM-17Product Origin:

FujianShipping Port:

Xiamen/ShanghaiMin Order:

1

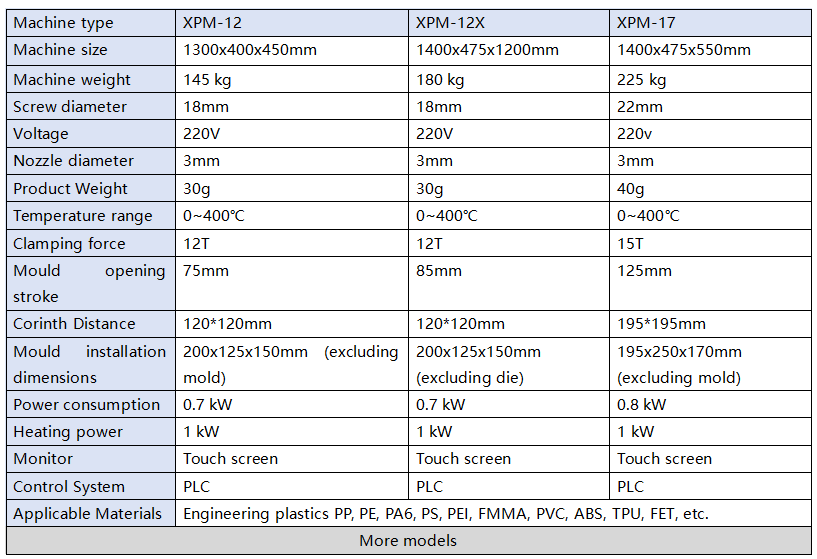

Injection moulding machine is a kind of machine that heats and melts plastic materials, then injects the molten state of plastic into the mould cavity through high pressure, and forms products after cooling. It is widely used in the production of various plastic products, such as daily necessities, electronic product shells, automobile parts and so on. The injection moulding process involves heating, injection, pressure holding, cooling, demoulding and other steps, and the whole process is highly automated and efficient.

- Efficient production:Injection molding machine can achieve high-speed, continuous production of plastic products, greatly improving production efficiency.

- Precision injection molding: It has a precise injection control system, which can accurately control the injection amount, pressure and speed of plastic materials, ensuring the dimensional accuracy and quality stability of the product.

- Diversified design: The injection molding machine can change the mold according to different production needs, and produce plastic products of various shapes, sizes and colors, with strong production flexibility.

- Energy saving and environmental protection: Some injection molding machines use advanced energy-saving technologies, such as frequency conversion control, energy-saving motors, etc., which can reduce energy consumption and meet the requirements of energy saving and environmental protection.

- Easy operation: The operation interface of the injection molding machine is usually designed to be simple and intuitive, easy to operate, and the operator can quickly pick up and start production.

- Safety: Injection molding machines have a variety of safety devices, such as safety doors, emergency stop buttons, overload protection, etc., to ensure the safety of operators and equipment.

- Reliable and stable: The injection molding machine uses high-quality mechanical and electrical components, stable structure, reliable operation, low failure rate, and can work statically for a long time.

- Highly automated: Advanced injection molding machines are equipped with advanced automation control systems to achieve fully automated production, improving production efficiency and product consistency.

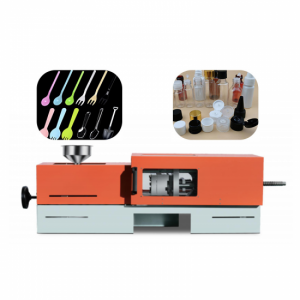

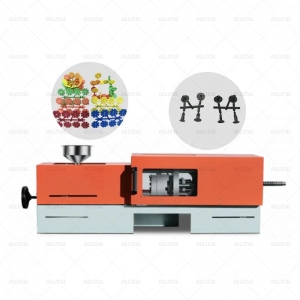

CRTOP Brand Small Horizontal Type Plastic Injection Moulding Machine

CRTOP Brand Small Horizontal Type Plastic Injection Moulding Machine

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

CRTOP Brand Lab Small Horizontal Type Plastic Injection Molding Machine

CRTOP Brand Lab Small Horizontal Type Plastic Injection Molding Machine

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Desktop Small PP PE PA6 PS PEI PMMA PVC ABS TPU PET Plastic Electric Mould Injection Molding Machine

Desktop Small PP PE PA6 PS PEI PMMA PVC ABS TPU PET Plastic Electric Mould Injection Molding Machine

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Horizontal PVC ABS PC PlasticBottle-Cap Making Injection Molding Machine

Horizontal PVC ABS PC PlasticBottle-Cap Making Injection Molding Machine

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Lab Injection Molding Machine Table Injection Molding Machine

Lab Injection Molding Machine Table Injection Molding Machine

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Plastic Injection Molding Machine With Servo Motor Tableware Injection Molding Machine

Plastic Injection Molding Machine With Servo Motor Tableware Injection Molding Machine

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

High Quality Full Automatic Plastic Injection Molding Machine

High Quality Full Automatic Plastic Injection Molding Machine

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Horizontal Injection Molding Machine

Horizontal Injection Molding Machine

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel : +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Preform Injection Molding Machine Pet injection molding machine

Preform Injection Molding Machine Pet injection molding machine

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel : +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Copyright © One-stop Service for Printing Machinery-Xiamen CRTOP Machinery Co., Ltd