+86 18030169616

+86 18030169616

allen@crtopmachine.com

allen@crtopmachine.com

+86 18030169616

+86 18030169616

allen@crtopmachine.com

allen@crtopmachine.com

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

read more

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

read more

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

read more

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

read more

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

read more

With the rapid development of biotechnology and pharmaceutical industry, bioreactors, as core production equipment, are increasingly used in cell culture, enzymatic reaction, fermentation engineering ...

Min Order:

1Minimum Order Quantity:

1Operation method:

PLCScreen:

Touch ScreenCapacity:

100LWarranty:

1 year

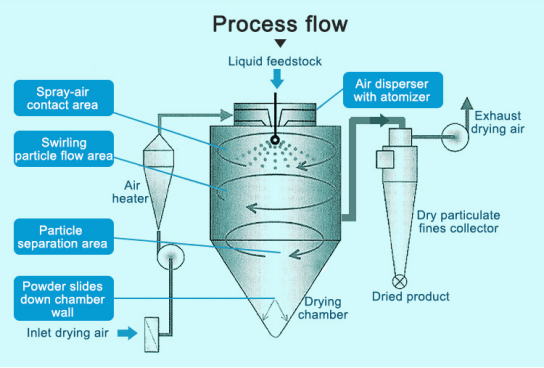

The working principle of spray drying equipment is that the air passes through the filter and heater, enters into the air distributor at the top of the drying tower, and then enters into the drying chamber uniformly in spiral shape. The material liquid is sent to the centrifugal atomiser at the top of the drying tower from the material liquid tank through the filter by the pump, so that the material liquid is sprayed into very small fog droplets, the material liquid and the hot air in contact with the concurrent flow, the water evaporates rapidly, and is dried into the finished product in a very short period of time. The finished product is discharged from the bottom of the drying tower and the cyclone separator, and the exhaust gas is discharged by the fan.

Spray drying equipment drying speed. Material liquid by centrifugal spray, the surface area is greatly increased, in the high temperature airflow, rapid evaporation of 95% -98% of the water, the completion of the drying time is only a few seconds. The use of parallel flow spray drying form can make the droplets and hot air flow in the same direction, although the temperature of the hot air is higher, but because the hot air into the drying chamber immediately contact with the spray droplets, the indoor temperature drops sharply, and the wet bulb temperature of the material is basically unchanged, and therefore is also suitable for drying of heat-sensitive materials.

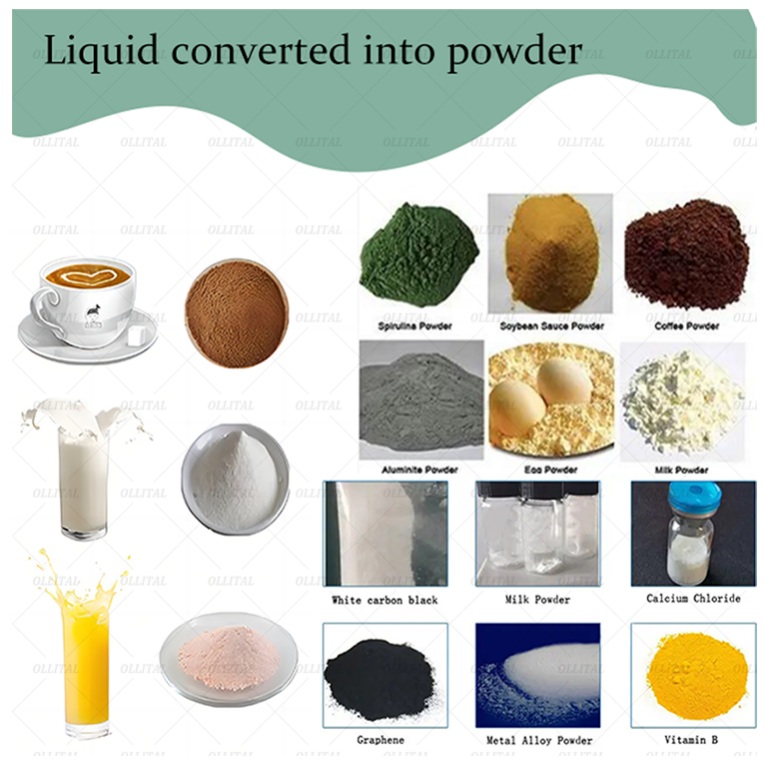

Wide range of use. According to the characteristics of the material, it can be dried by hot air or cold air, and a large number of products with great differences in characteristics can be produced with this, commonly used are: polymers and resins, dyes, pigments, ceramics, glass, rust removers, carbohydrates, dairy and egg products, ravaging acids, slaughterhouse by-products, detergents and surfactants, fertilisers, organic compounds, inorganic compounds, instant food and so on.

5L 10L 15L Milk Egg Instant Coffee Ceramic Powder Centrifugal Precio Para Spray Dryer Machine

5L 10L 15L Milk Egg Instant Coffee Ceramic Powder Centrifugal Precio Para Spray Dryer Machine

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Lab 2L 5L 10L Lab Small Mini Food Egg Coconut Milk Pharmaceutical Ceramic Chemical Ceramic Nano Centrifugal Spray Dryer

Lab 2L 5L 10L Lab Small Mini Food Egg Coconut Milk Pharmaceutical Ceramic Chemical Ceramic Nano Centrifugal Spray Dryer

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

1.5-2 L/h Mini Lab Coffee Milk Powder Spray dryer

1.5-2 L/h Mini Lab Coffee Milk Powder Spray dryer

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Lab Coffee Tea Plant Milk Powder Spray Dryer

Lab Coffee Tea Plant Milk Powder Spray Dryer

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Industrial Centrifugal Nozzle Spray Dryer Machine

Industrial Centrifugal Nozzle Spray Dryer Machine

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

3000ml/h Lab Milk Spray Dryer Powder Machine

3000ml/h Lab Milk Spray Dryer Powder Machine

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Lab PLC Control System Mini Stainless Steel Spray Dryer

Lab PLC Control System Mini Stainless Steel Spray Dryer

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel: +86 18030169616 Email: allen@crtopmachine.com jackson@crtopmachine.com

Coffee Tea Flavored Meat Fat-rich Milk Powder Spray Dryer

Coffee Tea Flavored Meat Fat-rich Milk Powder Spray Dryer

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Atomization Vacuum Milk Centrifugal Spray Dryer

Atomization Vacuum Milk Centrifugal Spray Dryer

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Copyright © One-stop Service for Printing Machinery-Xiamen CRTOP Machinery Co., Ltd