Food additives play a vital role in the modern food industry. They are used to improve the color, aroma and taste of food, extend the shelf life, enhance the nutritional value, etc. In the production process of food additives, drying technology is a key link. Spray dryers have become important equipment in the production of food additives due to their high efficiency, uniformity and rapid drying characteristics. This article will discuss in detail the application, working principle, advantages and selection guide of spray dryers in the production of food additives.

1. Overview of Food Additives

Food additives refer to chemically synthesized or natural substances added to food to improve food quality and color, aroma, and taste, or for preservation and processing needs. Common food additives include sweeteners, acidulants, pigments, preservatives, antioxidants, thickeners, etc. The quality of food additives directly affects food safety and consumer health, so every link in the production process must be strictly controlled, especially the drying process.

2. Working principle of spray dryer

The working principle of spray dryer is as follows:

-

Material pretreatment:

Liquid materials are pretreated by filtering, homogenizing and other pretreatment steps to ensure the purity and uniformity of the materials. -

Atomization:

The pretreated materials are sent to the atomizer through a high-pressure pump, and the atomizer disperses the liquid materials into tiny droplets. Common types of atomizers are centrifugal, pressure and airflow atomizers. -

Drying:

The atomized droplets are in contact with hot air in the drying tower, and the hot air is usually heated to an appropriate temperature by an air heater. The droplets quickly evaporate water under the action of hot air to form dry powder. -

Collection:

The mixture of dried powder and air is separated by a cyclone separator, the powder is collected in the collector, and the exhaust gas is discharged through the exhaust system.

3. Application of spray dryer in food additive production

-

Sweetener production:

Spray drying technology is widely used in the production of sweeteners, such as maltitol, sorbitol, etc. Through spray drying, sweeteners can be made into uniform powders, which are easy to store and transport while maintaining their sweetness and stability. -

Acidulant production:

Food acidulants such as citric acid and malic acid are usually dried by spray drying technology. Spray drying can quickly evaporate water, prevent acidulants from decomposing at high temperatures, and ensure product quality. -

Pigment production:

Natural pigments such as carotene and capsanthin are made into powders by spray drying technology, which can maintain the brightness and stability of the pigments and are widely used in food processing. -

Preservative production:

Common food preservatives such as potassium sorbate and sodium benzoate can be made into uniform powders by spray drying technology, which is convenient for uniform addition during food processing and improves the preservative effect.

4. Advantages of spray dryer

High efficiency and energy saving:

Spray dryer has fast drying speed and can complete the drying process within a few seconds, significantly improving production efficiency and saving energy consumption.

High product quality:

Spray drying can produce uniform, fluid and soluble powder products to ensure the quality and performance of food additives.

Wide application range:

Spray drying technology is suitable for various heat-sensitive materials and food additives that need to maintain their original characteristics, such as vitamins, enzyme preparations, etc.

Environmental protection and hygiene:

The spray dryer adopts a closed system to avoid contact between materials and the external environment, reduce the risk of pollution, and meet the hygiene requirements of food production.

5. How to choose a suitable spray dryer

-

Understand the material characteristics:

When choosing a spray dryer, you need to fully understand the physical and chemical properties of the material to be dried, such as viscosity, solid content, thermal sensitivity, etc., in order to choose the appropriate atomizer and drying parameters. -

Determine the production scale:

Choose the appropriate spray dryer model and specifications according to production needs. Small laboratory spray dryers are suitable for research and testing, and large spray dryers are suitable for industrial production. -

Consider the material of the equipment:

Spray dryers of different materials are suitable for different materials and applications, such as stainless steel for the food and pharmaceutical industries, and corrosion-resistant materials for the chemical industry. -

Evaluate equipment performance:

Choose equipment with efficient atomization and uniform drying performance, while considering the energy consumption, maintenance cost and ease of operation of the equipment.

6. Our Spray Drying Equipment

When choosing a spray dryer, it is crucial to choose a reliable supplier. Our company is committed to providing high-quality spray drying equipment to meet the diverse needs of customers. The following are our advantages:

Advanced technology:

Our spray dryer adopts advanced atomization technology and heat exchange system to ensure efficient drying and high-quality products. Our equipment has been strictly tested and verified, with stable performance and long life.

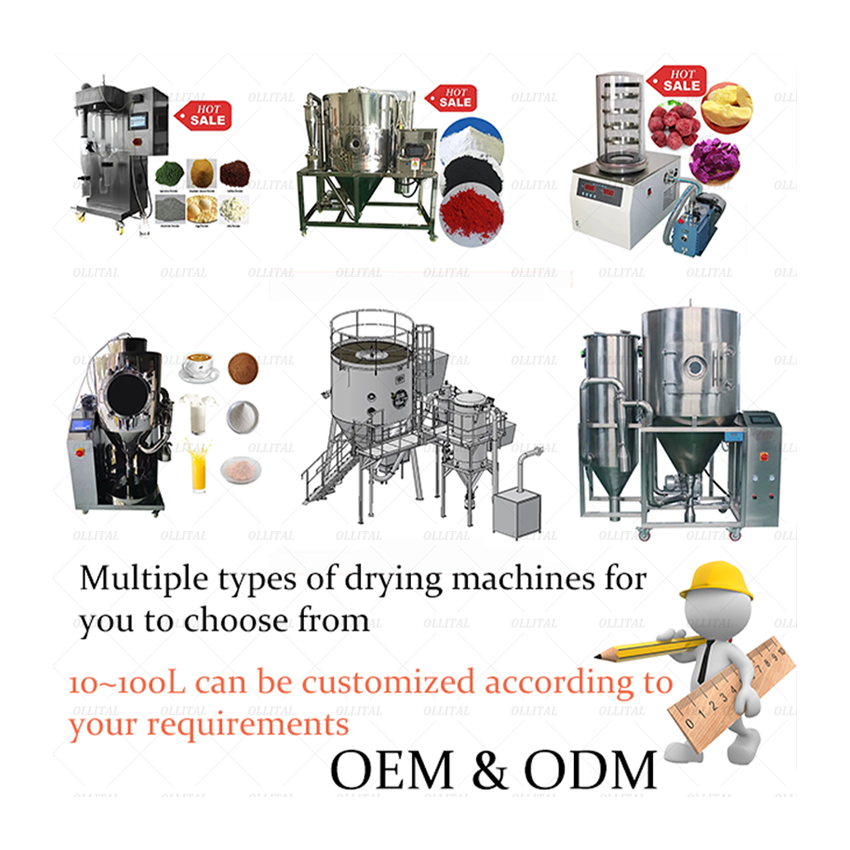

Diverse choices:

We provide a variety of specifications from laboratory small spray dryers to industrial large spray dryers, suitable for production needs of different scales. Whether it is small-scale laboratory research or large-scale industrial production, we can provide suitable solutions.

High-quality materials:

Our equipment uses high-quality stainless steel and corrosion-resistant materials to ensure the durability and safety of the equipment, and meets the hygiene standards of food and drug production. Our spray dryer design takes into account the needs of easy cleaning and maintenance, reducing equipment downtime and improving production efficiency.

Professional services:

We provide comprehensive pre-sales consultation, equipment installation, operation training and after-sales maintenance services. Our technical team is experienced and can provide customers with professional technical support and solutions. Whether it is equipment selection, installation and commissioning, or operation training and maintenance, we can provide customers with a full range of services to ensure that customers can use the equipment efficiently and solve practical problems in production.

By using our spray drying equipment, customers can significantly improve production efficiency, improve product quality, reduce production costs, and achieve sustainable development. We look forward to working with you to jointly promote the development and application of spray drying technology.

If you have any questions or needs, please feel free to contact us. We will wholeheartedly provide you with the best quality products and services.

+86 18030169616

+86 18030169616 allen@crtopmachine.com

allen@crtopmachine.com