Spray dryers have become indispensable equipment in many industries due to their excellent efficiency and flexibility. The core advantage of this equipment is that it can dry liquid materials into powder products, with a simple production process and high efficiency. The powder prepared by the spray dryer has uniform composition, moderate particle size, good fluidity, easy storage and use, and greatly improves production efficiency and the possibility of quality control. Whether in the pharmaceutical, food processing or chemical fields, spray dryers have become an important force in promoting the development of the industry with their unique functions and advantages.

The principle and advantages of spray dryer

- A spray dryer is a drying device used to process solutions, suspensions, sludge and other materials. It uses a spray method to atomize the material into droplets, disperse it in hot air, and contact it with the hot air in the form of co-current, countercurrent or mixed flow, so as to quickly evaporate the water and achieve drying. This technology eliminates the unit processes such as concentration, filtration and crushing, and can obtain a granular product at one time. The drying time is very short, usually only a few seconds to tens of seconds.

- The spray dryer has the advantages of maintaining the stability of active ingredients, high production efficiency, stable product quality, energy saving and environmental protection, convenient maintenance, long service life, easy industrial production, wide range of application, strong versatility and adaptability, etc.

Types of Spray Dryers

There are many types of atomization methods for spray dryers. According to the atomization mechanism, they can be divided into three common types: centrifugal, airflow and pressure.

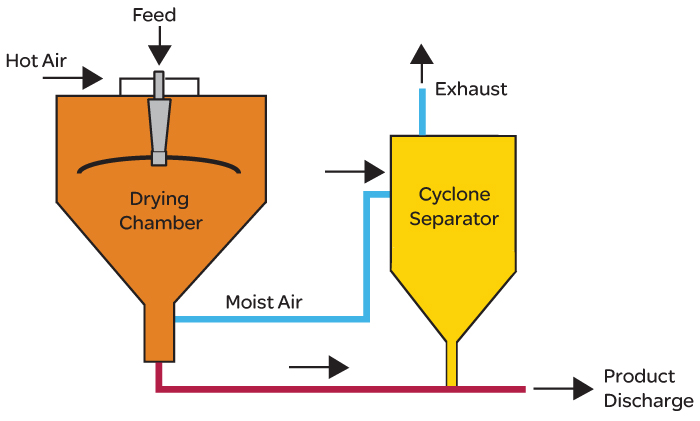

- Centrifugal spray dryers use centrifugal force to eject liquid substances from the center to the outside to form tiny water droplets. This type of nozzle generally rotates at high speed, which can generate strong centrifugal force to turn the droplets into particles. The finished product is discharged from the bottom of the drying tower and the cyclone separator, and the exhaust gas is discharged by the fan. The structure of the centrifugal spray drying device is generally simple, but it requires a higher speed and a suitable nozzle diameter to achieve the ideal atomization effect.

- Airflow spray dryer uses high-speed jet air or water vapor from the nozzle to disperse the liquid into tiny droplets by friction, and fully contact with the hot air to complete the heat transfer. This process does not exceed 30 seconds. It can effectively process high-viscosity materials, which is unmatched by other spray drying.

- Pressure spray dryer uses an airflow diaphragm pump to deliver materials at high pressure, spray out mist droplets, and then fall down in parallel with the hot air. Most of the powder particles are collected by the discharge port at the bottom of the tower, and the exhaust gas and fine powder are separated by a cyclone separator. The exhaust gas is discharged through an exhaust fan, and the powder is set in the powder collecting pipe under the cyclone separator. A secondary dust collector can also be set at the outlet of the fan to recover the dust.

Application of spray dryer

Spray dryers are widely used in the food industry. In the dairy processing process, liquid dairy products such as milk can be dried to make milk powder, whey powder, etc. It has high utilization value in infant food, nutritional supplements and special foods. Spray drying can be used to dry raw materials and make them into powder, which is convenient for storage, transportation and use. Spray drying can make grain and wheat flour more convenient to store and transport, and improve their stability and antioxidant capacity.

In the production of traditional Chinese medicine, the water content in the extract is high and volatile. The spray drying method can quickly remove the water, retain the effective ingredients, and improve the quality of the medicinal materials. The traditional Chinese medicine particles prepared by the spray drying method are uniform, small, easy to dissolve and absorb, and improve their bioavailability. Direct preparation of traditional Chinese medicine preparations can directly make traditional Chinese medicine extracts, extract powders, etc. into dry particles.

In the chemical industry, small and medium-sized spray dryers are widely used in the chemical industry, such as preparing granular substances, preparing catalysts, drying dyes, etc. They can quickly form fine particles of liquid materials, thereby achieving the purpose of controlled drying.

+86 18030169616

+86 18030169616 allen@crtopmachine.com

allen@crtopmachine.com