Introduction: Technical innovation of magnetic stirring reactor

As modern industry's demand for refined operations continues to grow, magnetic stirring reactors have gradually become key equipment in chemical industry, pharmaceuticals and other fields. With magnetic coupling technology, the reactor combines contactless stirring with high sealing performance, providing a reliable solution for demanding production processes.

Core Features: Innovative combination of contactless and high sealing

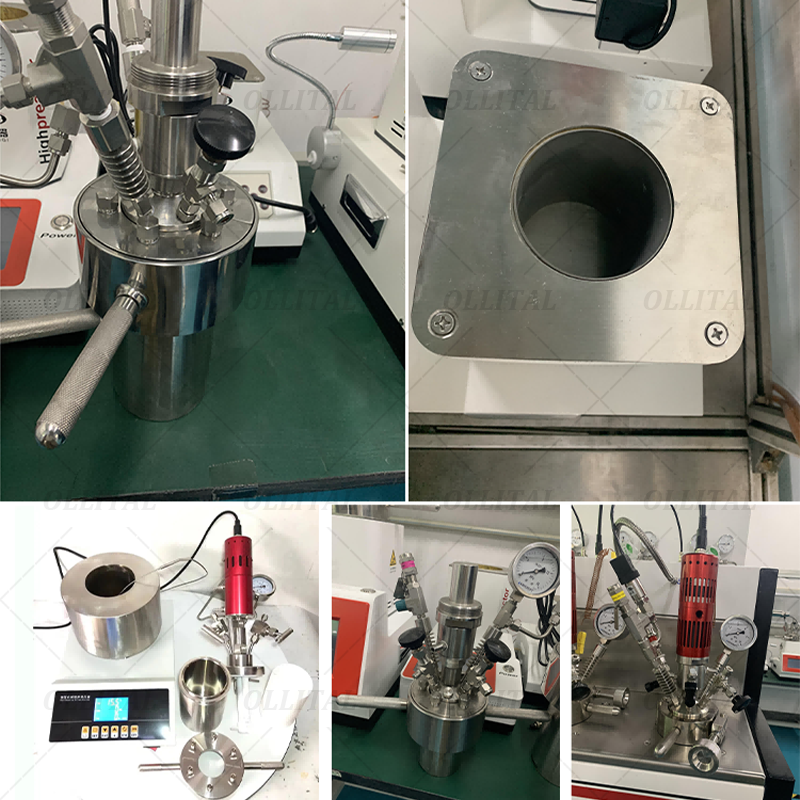

Shaftless stirring to improve purity: The magnetic stirring reactor uses magnetic coupling technology to separate the stirrer from the motor and achieve shaftless drive. This design eliminates the sealing problems caused by traditional stirring shafts and significantly reduces the risk of leakage, thereby ensuring high purity and low pollution in the reaction process.

Enhanced sealing: Due to the shaftless seal design, the magnetic stirred reactor is particularly suitable for handling highly corrosive or highly toxic chemicals. Its excellent sealing performance ensures safety and stability under complex reaction conditions, and is especially suitable for use in fields with strict environmental control such as pharmaceuticals and fine chemicals.

Wide range of applications: The design of magnetic stirred reactors makes them suitable for a variety of industrial applications, including homogeneous reactions in chemical production, aseptic operations in the pharmaceutical industry, and high-precision mixing operations in food and biotechnology. Its pollution-free mixing method and reliable sealing design make it a promising application in these fields.

Technical advantages and future development trends

Precise control and efficient production: Thanks to the combination of magnetic coupling and automated control systems, the magnetic stirring reactor can accurately adjust the stirring speed, temperature and pressure. This precise control not only improves reaction efficiency, but also ensures the quality consistency of the final product and promotes industrial production of complex reaction processes.

Adapt to more harsh operating conditions: With the continuous advancement of technology, the design and materials of magnetic stirring reactors are constantly being upgraded. In the future, this kind of equipment will be able to better cope with operating requirements in high temperature, high pressure and highly corrosive environments, providing strong support for the development of new materials and the synthesis of high-performance compounds.

Market development and prospects

Steady growth in market demand: Globally, with the increase in industrialization, the market demand for magnetic stirring reactors continues to grow. Especially in high-demand industries such as pharmaceuticals and chemicals, this equipment has become the darling of the market because of its unique technical advantages.

International application trend: With the rise of emerging markets such as China, the application of magnetic stirring reactors has expanded from developed regions such as Europe and the United States to the world. The technical maturity and reliability of this equipment make it highly competitive in the international market, and its application scope will be further expanded in the future.

Conclusion

Magnetic stirring reactor plays an increasingly important role in modern industry with its non-contact stirring technology and excellent sealing performance. With the development of technology, this equipment will demonstrate its unique advantages in more fields and provide more reliable solutions for fine chemical industrial production.

+86 18030169616

+86 18030169616 allen@crtopmachine.com

allen@crtopmachine.com