+86 18030169616

+86 18030169616

allen@crtopmachine.com

allen@crtopmachine.com

+86 18030169616

+86 18030169616

allen@crtopmachine.com

allen@crtopmachine.com

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

read more

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

read more

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

read more

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

read more

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

read more

With the rapid development of biotechnology and pharmaceutical industry, bioreactors, as core production equipment, are increasingly used in cell culture, enzymatic reaction, fermentation engineering ...

SEND A MESSAGE :

WhatsA pp : +8618030169616 Tel .: +86 18030169616

Email : allen@crtopmachine.com Skype : +8618030169616

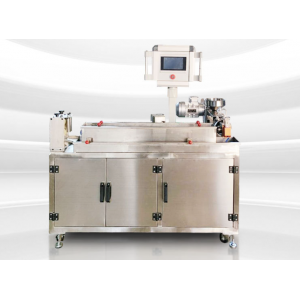

Item No.:

ZS-430BProduct Origin:

ChinaShipping Port:

XiamenMin Order:

1Lead Time:

T/TMinimum Order Quantity:

1Operation method:

PLCCapacity:

5 (kg/h)Warranty:

1 yearDimension(L*W*H):

1500X800X2000Product Description:

Extrusion blown film refers to the bi-fold plastic film obtained by continuously extruding the plastic melt through the die under the action of a certain temperature and a certain shearing force, which is inflated by compressed air, cooled by an air ring and traction by frequency conversion. crafting process. This machine is mainly used to detect the feasibility of blown film of polymer materials and the colloidal condition in the material, as well as the dispersion of colored dispersions, control mixtures, and extrudates. Machine applicable materials: HDP, LDPE, LLDPE blown film grade PP + masterbatch, filler masterbatch, plastic additives, functional masterbatch

The feature for dispersion kneader:

1. The extruder is driven by an international brand variable frequency motor, which has stable plasticization and good consistency;

2. Extrusion device: The barrel and screw are the key parts of the machine, and the plasticization and extrusion of materials are carried out here. The barrel and screw are made of high-quality nitrided steel 38CrMoALA. The surface has undergone a week of gas nitriding treatment. It has good mechanical properties such as high hardness, wear resistance and corrosion resistance, which greatly extends its service life.

3. The barrel heating of this machine adopts cast aluminum heater and stainless steel air hood, which is beautiful and energy-saving, good heat resistance, long service life, uniform heat transfer, and easy to replace; the fan is cooled through the set channel (automatically open the fan for cooling when the temperature is over ), the cooling effect is good.

4. Transmission device: the drive motor is directly connected with the reducer, and the output shaft of the reducer is connected with the screw to drive the screw to rotate. The transmission device has compact structure, stable operation and strong bearing pressure.

5. Emergency shutdown device and various safety protections to ensure the safety of operators;

6. Highly intelligent and easy to operate.

Technical Parameters

WhatsApp: +8618030169616 Tel.: +86 18030169616(Only supports mobile phone dialing)

Email: Jackson@crtopmachine.com Skype: +8618030169616

Add.: Haicang District, Xiamen , Fujian , China.

Multi-layer Lab Cast Film Machine Line PP PE PET Sheet Cast Film Extrusion Machine with Twin Screw Extruder Film Casting

Multi-layer Lab Cast Film Machine Line PP PE PET Sheet Cast Film Extrusion Machine with Twin Screw Extruder Film Casting

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Lab Cast Stretch Film Extrusion Machine with Twin Screw Extruder Film Casting Line PP PE PET Sheet Cast Film Extrusion Machine

Lab Cast Stretch Film Extrusion Machine with Twin Screw Extruder Film Casting Line PP PE PET Sheet Cast Film Extrusion Machine

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Plastic bag making machine Fresh film Plastic film blowing machine plastic extruder

Plastic bag making machine Fresh film Plastic film blowing machine plastic extruder

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Pe Film Blowing Machine Plastic Sheet Extruder Machinery

Pe Film Blowing Machine Plastic Sheet Extruder Machinery

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel : +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Batch And Continuous Bioreactor Bioreactor Industrial

Batch And Continuous Bioreactor Bioreactor Industrial

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

2021 New Product PVC Pipe Laser Pinter 20w 30w 50w Hot Sale Long Service Life Easy Operation High Quality

2021 New Product PVC Pipe Laser Pinter 20w 30w 50w Hot Sale Long Service Life Easy Operation High Quality

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

3000ml/h Lab Milk Spray Dryer Powder Machine

3000ml/h Lab Milk Spray Dryer Powder Machine

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Glass Lab Bioreactor 10l Glass Bioreactor Algal Culture

Glass Lab Bioreactor 10l Glass Bioreactor Algal Culture

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Electric Heating Type Lab Two Roll Mixing Mill

Electric Heating Type Lab Two Roll Mixing Mill

SEND A MESSAGE : WhatsA pp : +8618030169616 Tel .: +86 18030169616 Email : allen@crtopmachine.com Skype : +8618030169616

Copyright © One-stop Service for Printing Machinery-Xiamen CRTOP Machinery Co., Ltd